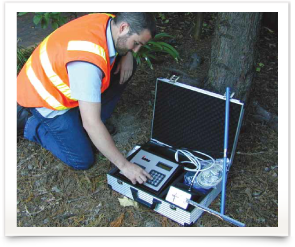

ENSPEC operates an IML Electronic Fracture Meter 3; traditionally these units have only been used in laboratories for testing wood strengths for scientific research.

ENSPEC uses the Electronic Fracture Meter 3 (EFM3) to measure the quality and strength of tree wood by testing core samples taken from a tree’s trunk or branch. The EFM3 electronically breaks an increment core of wood and directly records the kN strength into the computer, which then provides a digital printout of the wood’s radial, tangential and compression strength against the various stages of wood degradation; this system eliminates any chance of human error.

Where there is concern about wood strength loss in a tree or branch the EFM3 can be used to determine the structural integrity of incipient and decayed wood.

A fully trained ENSPEC operator uses the EFM3 to extract a 5 mm diameter core sample from the tree using a specially designed increment borer. This core is carefully placed in the Fracture Meter so that the wood grain is aligned in the instrument ensuring it is tested in a manner that simulates the actual loading in a tree. The instrument then automatically applies a bending load to the core and the resisting forces are measured until failure of the core occurs.

The bending strength can be measured in both the radial and tangential directions and is expressed in Newtons or MPa. Typical values range from 8 to 34 MPa (radial) and 6 to 14 MPa (tangential). The compression strength can also be measured with typical values being in the range of 15 to 45 MPa.

From this test the bending strength and compression strength of the wood is measured and the values cross referenced to tables for green wood samples. The trained ENSPEC operator interprets the results and provides the client with a professionally written detailed report. This can assist managers to make informed decisions regarding the appropriate management of the tree.