ENSPEC uses the Diagnostic Drill (IML-RESI F500) to measure internal wood properties in trees or wooden poles. This is an invasive method of measurement and ENSPEC only uses this device as a last resort in specific circumstances. The Diagnostic Drill uses an extremely thin and long drill needle bit to make a small hole in the tree and as the drill needle rotates, the resistance to drilling is measured.

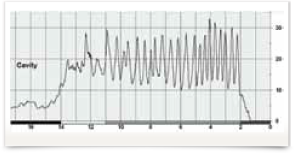

Highly trained and experienced ENSPEC staff use the drill to make a small hole in a tree or wooden pole. As the drill needle progresses through the wood the resistance and depth is recorded on a strip chart to show how strongly the drill must operate in order to pass through the wood. The depth of the drill is carefully measured so the chart curve is a record of the wood quality along the line of the drill path. The graph maps the wood profile giving a clear picture of the internal properties and wood quality of the tree or pole.

The Diagnostic Drill is able to accurately identify specific layers of wood. Solid wood has a high resistance to drilling and a corresponding high value on the strip chart. The softer decayed or fungi affected wood has a lower resistance to drilling and a corresponding lower value on the strip chart. Cavities offer no resistance to drilling and consequently have the lowest values on the chart.

Because the Diagnostic Drill is an invasive tool it must be used with caution; ENSPEC employs operators highly trained and experienced in its use to ensure any damage caused to the tree is kept to a minimum.

ENSPEC only uses this instrument as a last resort to gather evidence on the internal properties of trees. Such evidence may be used to identify and manage a tree that has internal defects that could lead to tree failure causing injury or damage to people or property.